Shell and Tube evaporators

16 July 2020How a plate heat exchanger works

Shell and Tube evaporators LSE - SSE

The main applications of dry-expansion evaporators are the water chilling in air conditioning plants, the liquid or brine solutions cooling in refrigeration plants, the water heating in heat pump systems.

LSE / SSE models are optimized for use with R134a, but can be used with the most common refrigerants; through the selection software and the support of our Technical Department, it will be possible to get the best solution for any working condition.

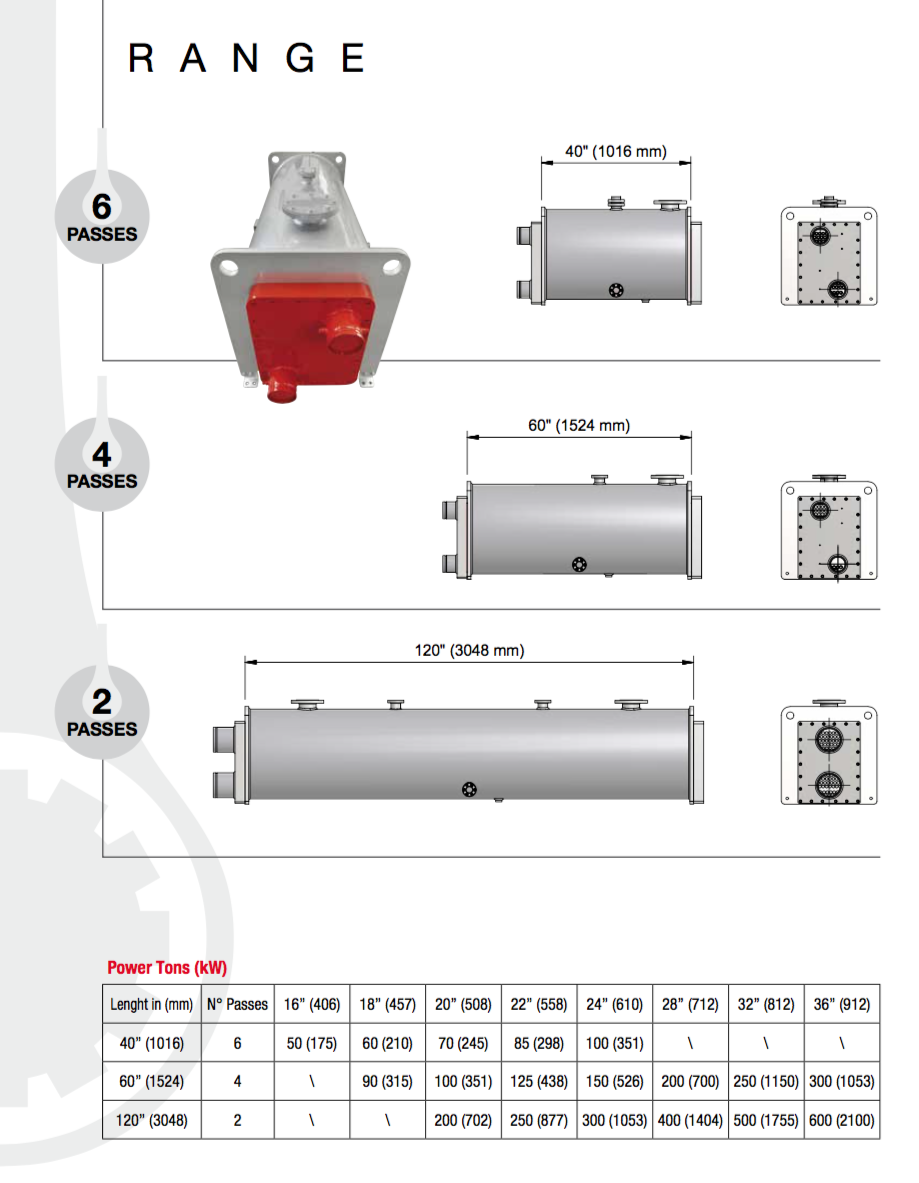

The ONDA shell & tube compact evaporators have cooling capacity range, at specified standard conditions, from 160 kW till 1600 kW, up to 4 refrigerant circuits.

The tube bundle, directly welded to the shell, is non-removable: the straight tubes configuration allows anyway to clean easily the inner of tubes.

This evaporators can guarantee a better thermal performance through a perfect counter-current flow, and the reduction of by-pass flow, thanks to strict

mechanical tolerances of the components.

Shell and Tube evaporators LPE - MPE - HPE

The main applications of our dry-expansion exchangers are the water, the liquid or brine solutions cooling in refrigeration plants and the hot water productio in heat pumps.

Suitable refrigerants are: HCFCs, HFCs, and others, unless they are compatible with material construction.

The ONDA shell & tube compact exchangers series have cooling capacity range, at specified standard conditions, from about 15

up to 1400 kW with 1 to 4 refrigerant circuits.

Hybrid Film Evaporator

12 May 2020How a plate heat exchanger works

Benefits

Onda has recently developed a new innovative evaporator to respond to an increasing efficiency market demand and a reduced refrigerant charge to balance the continuous refrigerants cost and taxes increase.

The “Hybrid Film“ evaporator combines the benefits of the pool boiling reliable performance and the falling film evaporator low refrigerant charge.

The concept of this innovative heat exchanger has been developed by R&D and validated in Onda’s laboratory with turbo (no oil) and screw compressor (with oil).

The core design belongs to Onda’s IPR and it is patent pending.

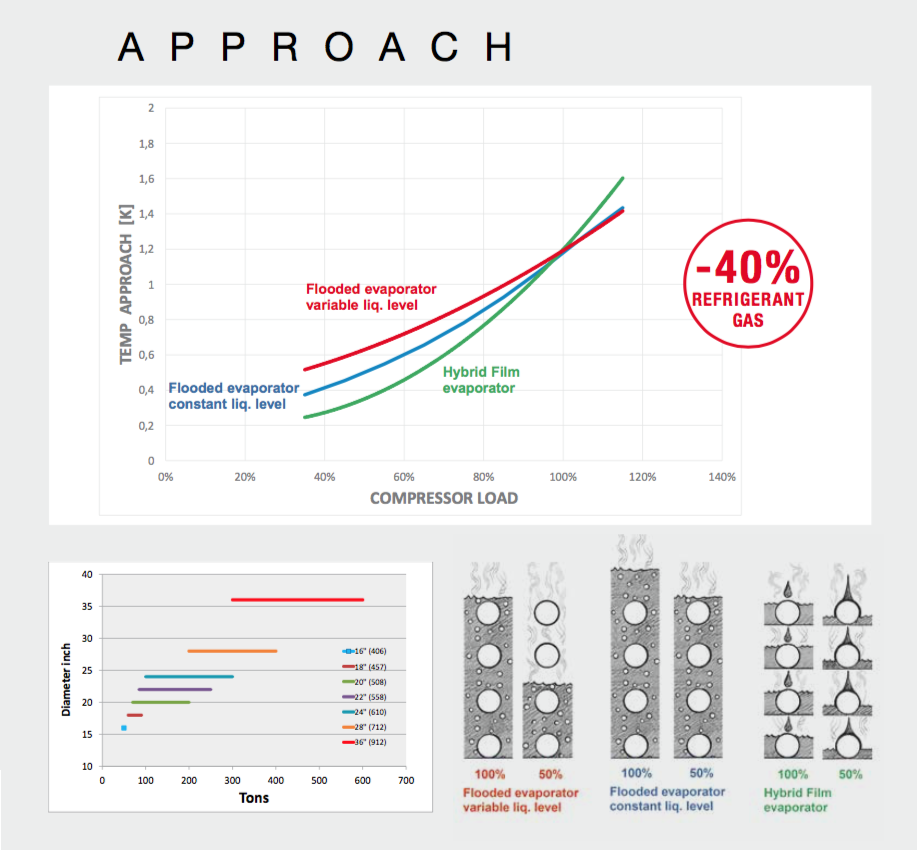

The Hybrid Film evaporator new distribution system allows to keep control of the refrigerant liquid around the tubes in all the different working conditions, at full load and at part load as well.

The amount of refrigerant liquid surroundings the tube is also optimized and reduced.

Approach

Part load: when moving < 80% of the load the hybrid lm is performing better with a reduced temperature approach with a positive impact on the chiller IPLV.

Similar performance is also expected with HFO R1234ze. Refrigerant charge reduction : the charge saving vs flooded is in a range of 35 – 40%.

You can download the catalogue in the link below :

https://www.onda-it.com/eng/products/shell-and-tube-heat-exchangers/hybrid-film-evaporator

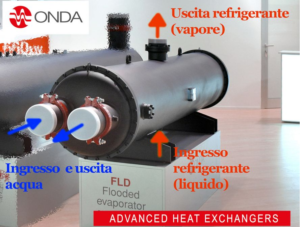

Flooded Evaporators

2 May 2020How a plate heat exchanger works

Flooded Evaporators

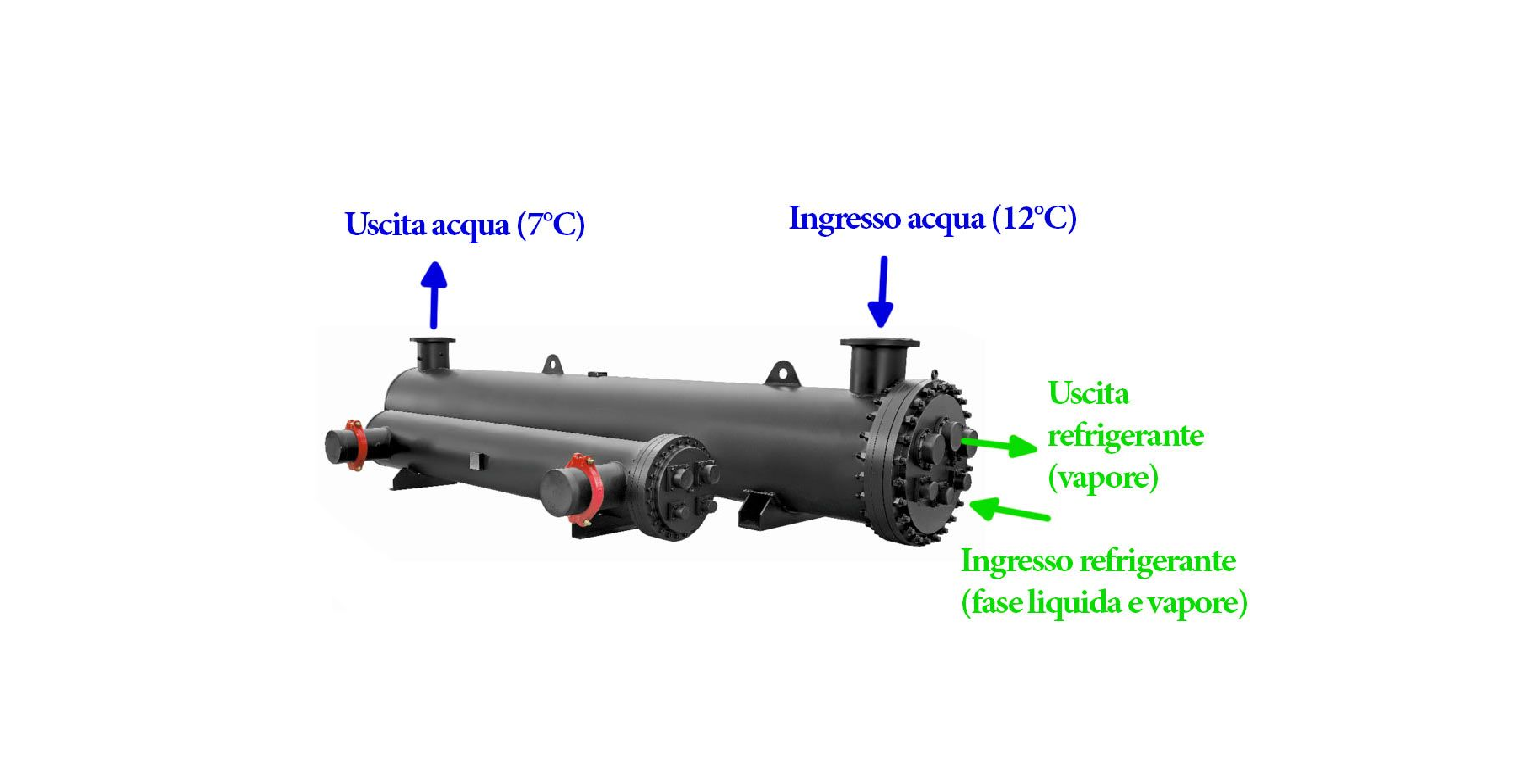

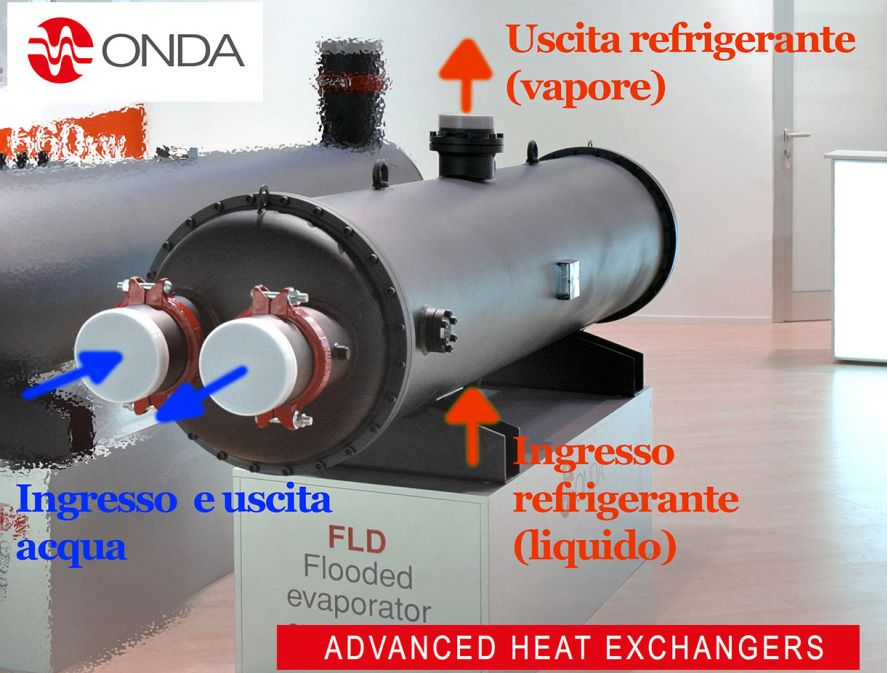

In the flooded evaporators, a pool of refrigerant in the shell is submerging the tubes to a set level.

As the refrigeration load varies, a refrigerant-level control acts to maintain the liquid level in the shell.

The refrigerant pool in the shell behaves as a flywheel, allowing the control of the flooded evaporator to successfully track the varying load of a batch process.

More than 7 years of specific experience and continue laboratory tests are combined in the ONDA flooded evaporators, the best flooded evaporator ever.

Designed for high efficiency water chillers in combination with oil-free compressors, they can guarantee an optimal performance even in

presence of screw compressors.

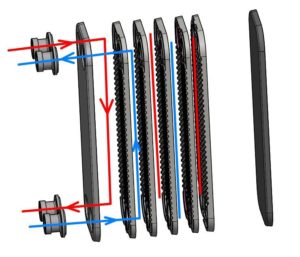

Brazed plate heat exchangers : Evaporation/Condensation/Single phase

15 November 2019How a plate heat exchanger works

Brazed plate heat exchangers: single-phase and two-phase

Plate heat exchangers have the general purpose of heating / cooling process fluids (for example water, oil, glycol, etc.)

In the two-phase field they are used as evaporator or condenser (using refrigerant fluids such as R134a, R1234ze, R410A, etc.) in a vapor compression refrigeration cycle.

In this article we will try to explain in simple way these types of heat exchangers.

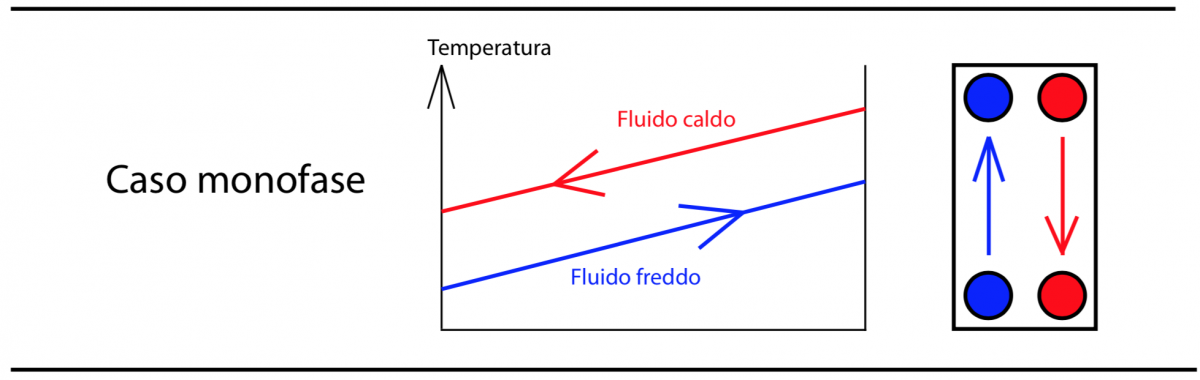

In the case of a single-phase process we have two fluids that enter the heat exchanger generating a perfect countercurrent flow, therefore, the hypothetical maximum outlet temperature of both fluids will be equal to the inlet temperature of the opposite fluid.

This could only happen if the exchange area tended to infinity, so in reality this cannot happen.

So let's see an example of a single-phase countercurrent flow, in which the cold fluid (in blue) enters and increases his temperature removing heat from the hot fluid (red) which is going to cool down, decreasing its temperature

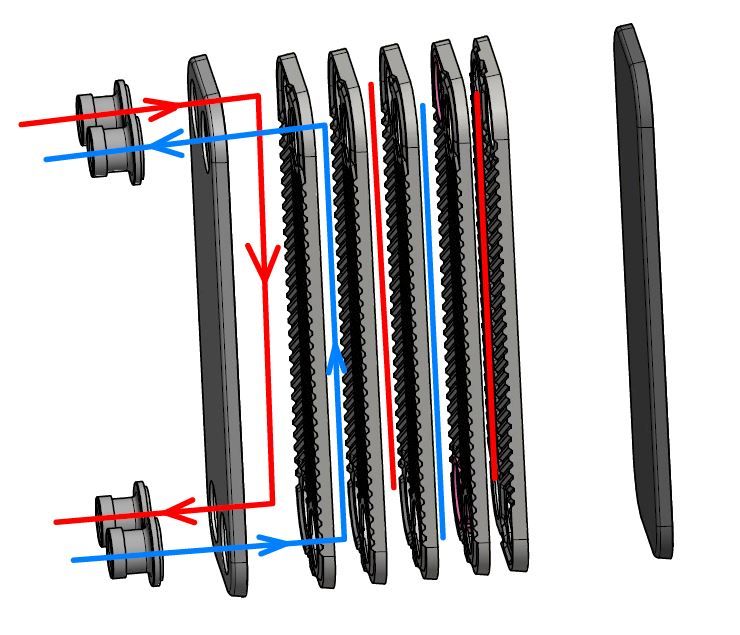

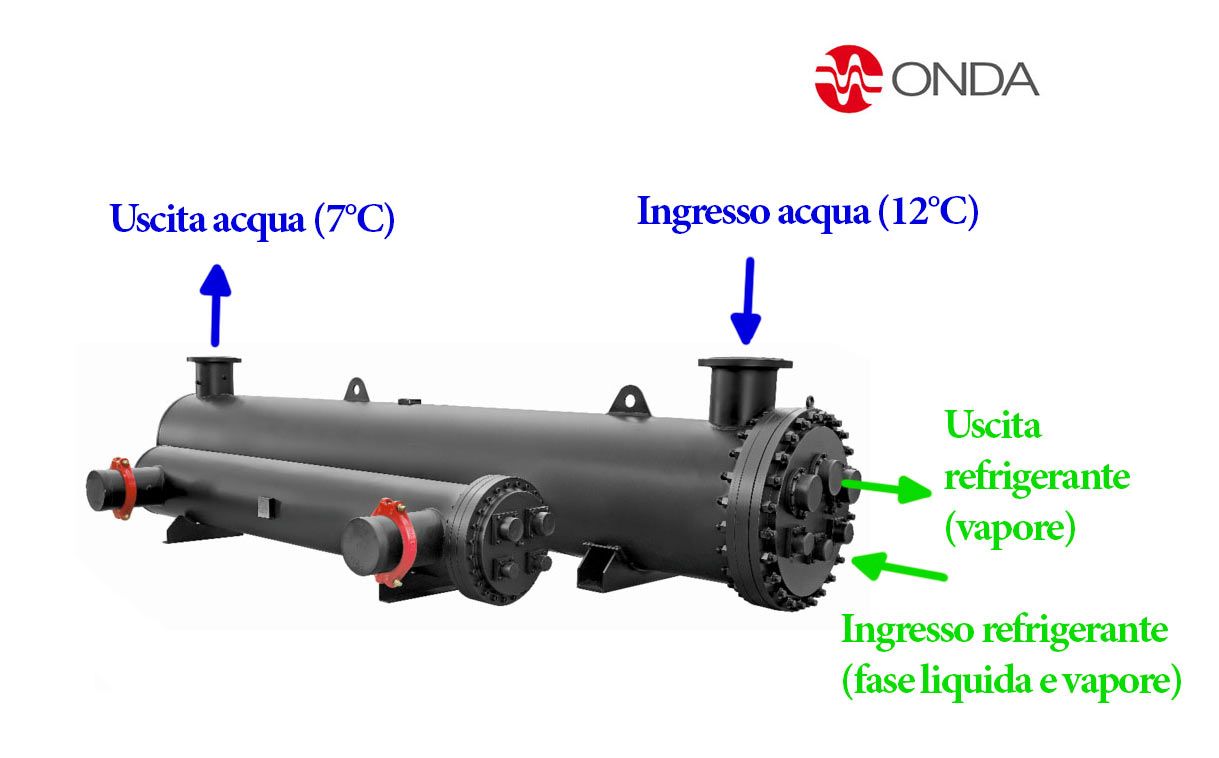

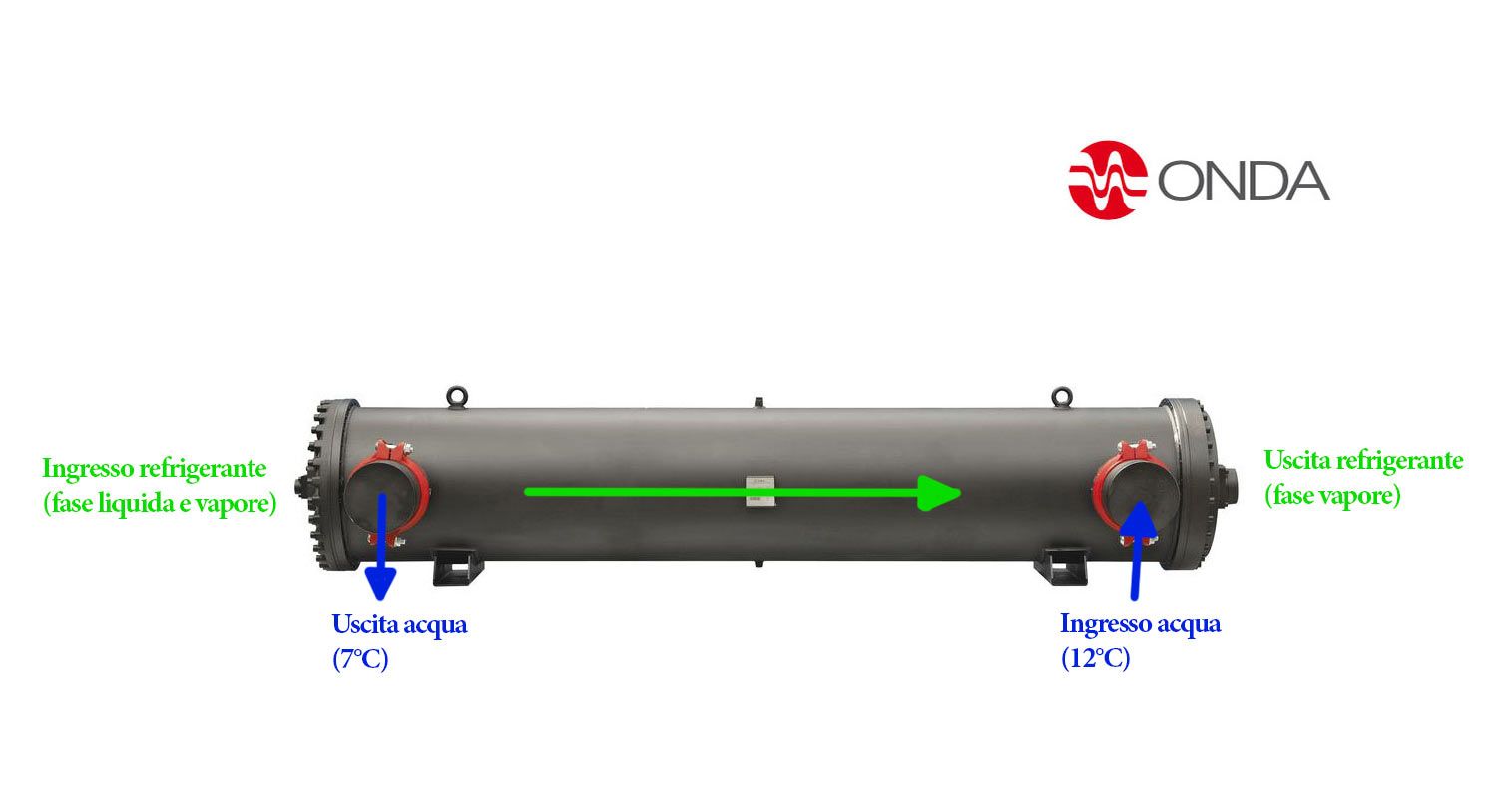

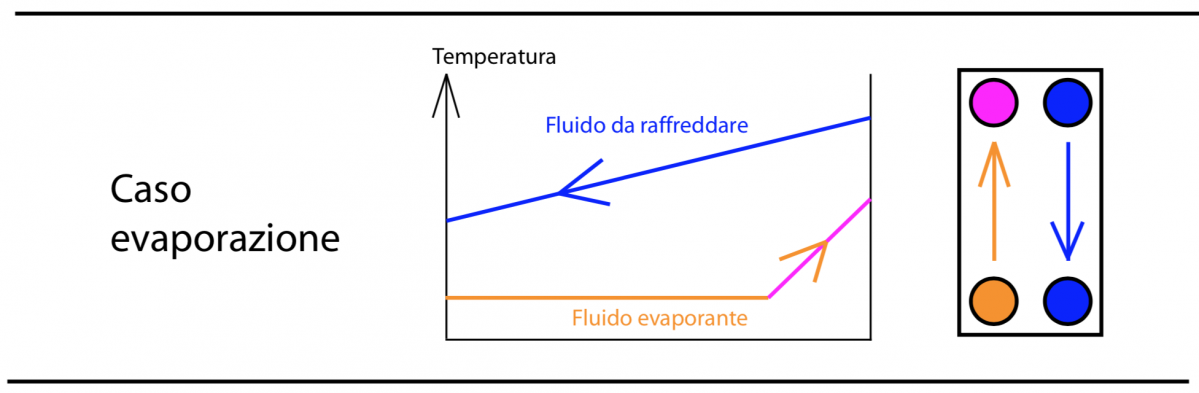

In the case of a plate heat exchangers evaporator, in general, the purpose is to cool down a process fluid by evaporating a refrigerant fluid at constant temperature.

By far the most common application is to cool water from 12 ° C to 7 ° C for air conditioning systems.

In this plate heat exchanger, the refrigerant fluid enters in liquid phase at high speed (in reality the inlet vapor quality goes from 0.2 to 0.3) and evaporates through the plate exchanger from the bottom upwards, removing heat from the fluid that flows on the other side.

The last part of the exchanger is used to overheat the already evaporated gas so that there is no return of liquid particles in the compressor to avoid breakage of the compressor itself.

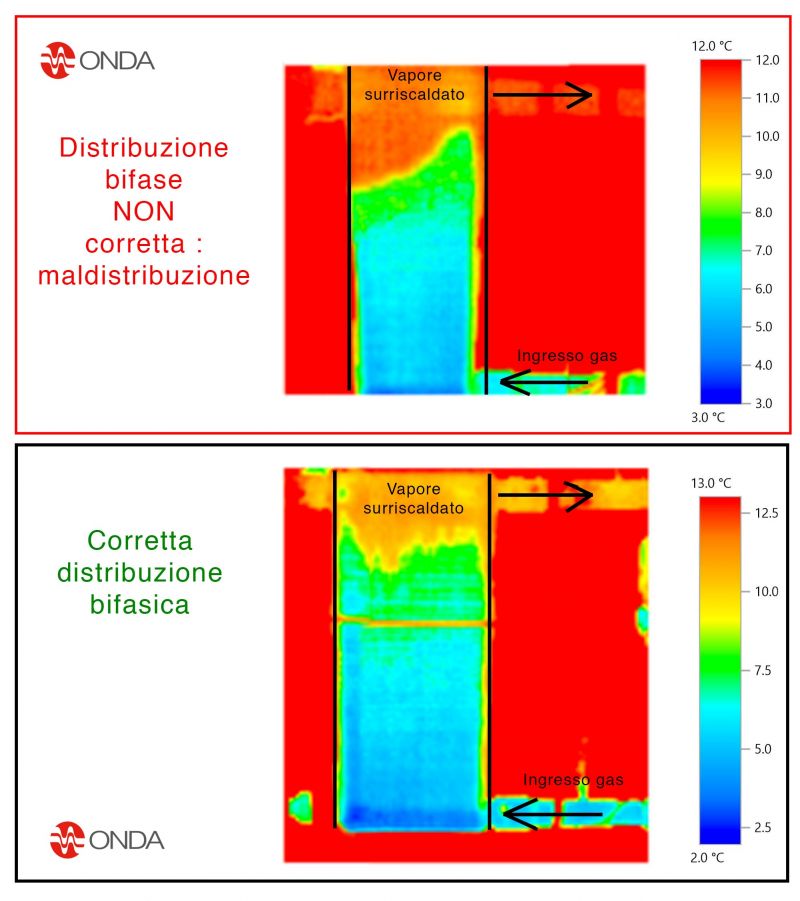

The most important part of this process of evaporation is the correct distribution of the two-phase fluid at the inlet of the heat exchanger.

The target is to introduce the same gas flow rate in every channel of the heat exchanger along all the package of plates.

Onda has patented a distribution system that allows gas to be distributed homogeneously along the entire exchanger.

As we can see in the figure, it can be seen that a correct distribution has a homogeneous overheating zone of the gas (in orange) from the beginning to the end of the exchanger.

If the distribution is not homogeneous we will have areas with more superheated steam and areas with less superheated steam, the operation of the chiller in this case may be unstable.

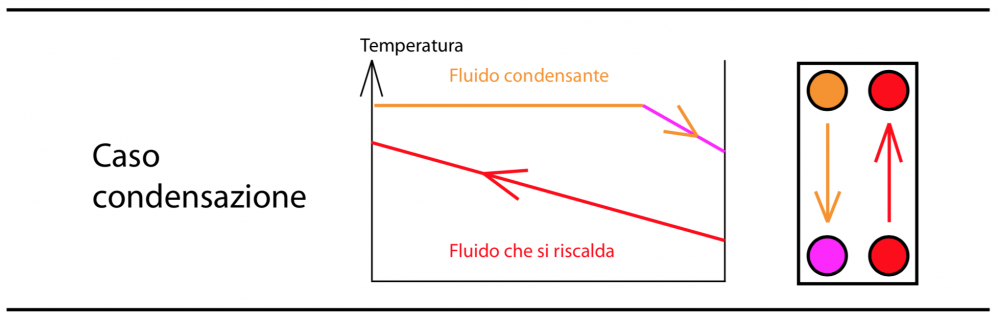

In the last case of brazed plate heat exchangers condenser, on the other hand, we have a refrigerant fluid in a gaseous state (generally at a high temperature about 60-70 °C) that condense at the expense of a fluid which, on the other side of the exchanger, is heating up.

In general the condensing temperature of the refrigerant is about 40°C and the fluid in the other side goes from 30 to 35°C.

The last part of the exchanger is used to subcooling the liquid condensate by a few degrees, usually 3-4°C.

In this case the superheated gas enters at the top and descends through the exchange plates, condensing until it becomes liquid and exiting at the bottom.

Enrico Golin

Onda S.p.A.

Shell and Tube Condenser

25 October 2019How a plate heat exchanger works

Shell and Tube Condensers

The main applications of the Shell & Tubes condensers are the condensation of refrigerant gas in the air conditioning and refrigeration plants, and heat recovery.

All refrigerants are suitable, provided they are compatible with the materials used for construction.

In standard conditions shell & tube condensers have an heat capacity between 10 kW and 2 MW.

Congress of refrigeration ICR2019

16 September 2019Archivio news

Onda attended the 25 th IIR International Congress of Refrigeration ICR2019, held in Montreal from August 25 th to 31 th, 2019.

Onda wanted to actively give its contribution to the research against global warming. An experimental and theoretical work on low-GWP refrigerants evaporating in new low-charge and high-efficiency heat exchangers was presented. The scientific study was entirely conducted inside Onda by the R&D team with the support of the internal Laboratory of Heat Transfer; in particular, it deals with a direct comparison between R134a and R1234ze(E) in the new Onda Hybrid Film Evaporator.

The paper presented at ICR2019 is referred as:

Giuseppe Censi, Loris Giancotti, Andrea Padovan, (2019) “Experimental comparison of the heat transfer performance of R134a and R1234ze(E) in a hybrid film evaporator”. Proc. of the 25th IIR International Congress of Refrigeration, August 25-31, Montreal, Canada, pp. 2706-2713.

and can be found in the “ICR2019 Book of Proceedings” at the official IIR/IIF website (http://www.iifiir.org/) or at the congress website (https://icr2019.org/).

If you are interested on receiving a free copy of the paper, please write to gcensi@onda-it.com specifying in the object “ICR2019 Onda paper request”, kindly reporting your name and, if you want, your affiliation (if any).

30th anniversary of Onda

When celebrating 30th anniversary of ONDA, we should recall the most important pictures of its own hystory. Not the first product done, neither the first sales in export nor the the first subsidiary opened but the families, the babies born, the first loans of the houses, the first day of school for sons or the vacation we ever dreamed. Because what the Company has done in 30 years is .... to make dreams come true; the dreams of all families working in ONDA. The most beautiful thing is ... that all colleagues participated to make our dreams come true!...

Happy birthday ONDA...

Onda Nordic OY

Onda Nordic

ONDA S.p.A. announces, in date 12th of June 2019, the acquisition of the majority of WTT OY, a Finnish manufacturing company leader in district cooling and heating substations.

WTT is succesfully operating, with its own subsidiaries in Scandinavian and Baltic area, in the business since more than 10 years.

WTT will join ONDA Group and will change its name into ONDA Nordic OY. The Sinergy between ONDA Nordic OY and the mother Company ONDA S.p.A. (founded more than 30 years ago by Mr. Giuseppe Sella) will strengthen the skills of products/production development and sales effectivness.

Mr. Pasi Mäkinen will cover the position of Managing Director of the Company. Together with Mr Mäkinen and Elisa Sella (Financial Controlling of ONDA S.p.A.)

will join the new Board Directors of ONDA Nordic.