Wieland-Onda

A new chapter has begun – we are pleased to announce the exciting development that we are now part of the @Wieland Group.

Founded over 200 years ago, Wieland is a family-owned global leader in the semi-finished copper and copper alloy industry. Wieland Onda will be part of Wieland’s business unit Thermal Solutions, that globally develops and manufactures sustainable and cutting-edge heating and cooling technologies such as high-performance tubes, heat exchangers, and solutions for electronics cooling. Stay tuned for new opportunities, innovations and capabilities for our customers and employees. #WielandOndaSrl

We'd like to thank everyone at Wieland for making us feel welcome and supporting us. #NewChapter #WielandOndaSrl formerly #ondaspa

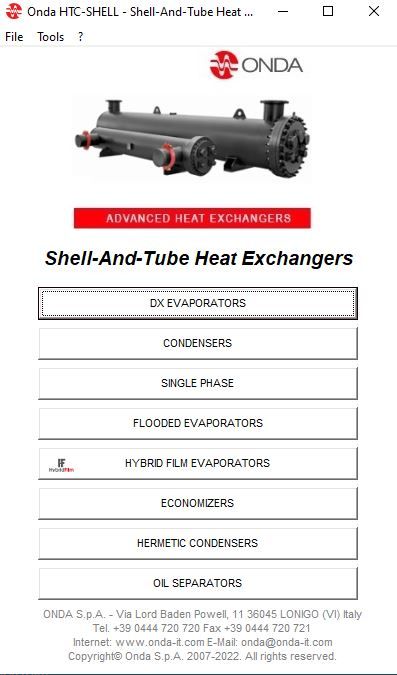

New software Onda-HTC-SHELL_3_100_0 !

We are proud to show you the new shell and tube software Onda-HTC-SHELL_3_100_0 !

You will find the new FSE straight tube evaporator, go to the download area to find it !

New software Onda-HTC-BPLATE_3_9_0 !

We are proud to show you the new brazed plate heat exchanger software Onda-HTC-BPLATE_3_9_0 !

You will find the new S727 - S608 - S101L - S16L , go to the download area to find it !

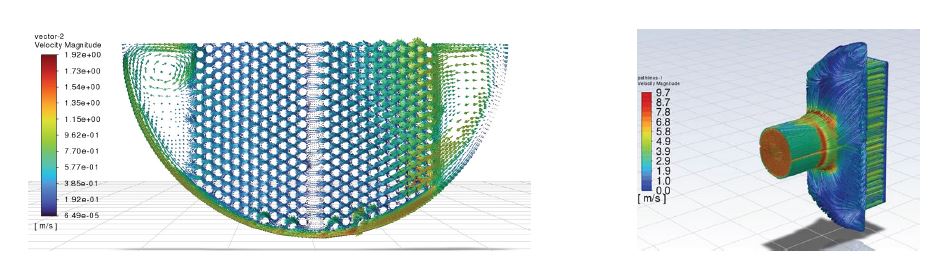

New FSE shell and tube evaporator

The new dry-expansion evaporator FSE has been developed to respond to Air Conditioning, Data Center and Process Cooling application demands. FSE employs a refrigerant distribution system which has been optimized to manage multiple refrigerants in order to respond to the new EU F-Gas regulation proposal with R290, R600a or with the traditional HFC, HFO low pressure refrigerants.

The FSE design has been optimized by R&D by using a fluid dynamic simulation analysis (CFD) and internal thermal design simulation tools. The efficiency of water side has been improved by reducing the pressure drop

Software HTC - Shell and Tube

The new shell and tube Wieland Onda HTC-SHELL 3.70.0 software is online !

You will find the new HDE, SPE and OVS !

New Brazed Plate Heat Exchanger S727

New S727 dual circuit evaporator

The new Onda Brazed Plate S727 is the larger plate in the BHE portfolio and it has been developed to respond to Air Conditioning and

Process Cooling applications with low pressure refrigerants as R1234ze, R515B, R513A and R134a.

The design of the plate corrugation pattern has been optimized thanks to a CFD analysis supported by thermal laboratory test.

New patented distribution system which allows to achieve stable performance with large plate package reaching a cooling capacity up to 700 kW .

Download the leaflet !

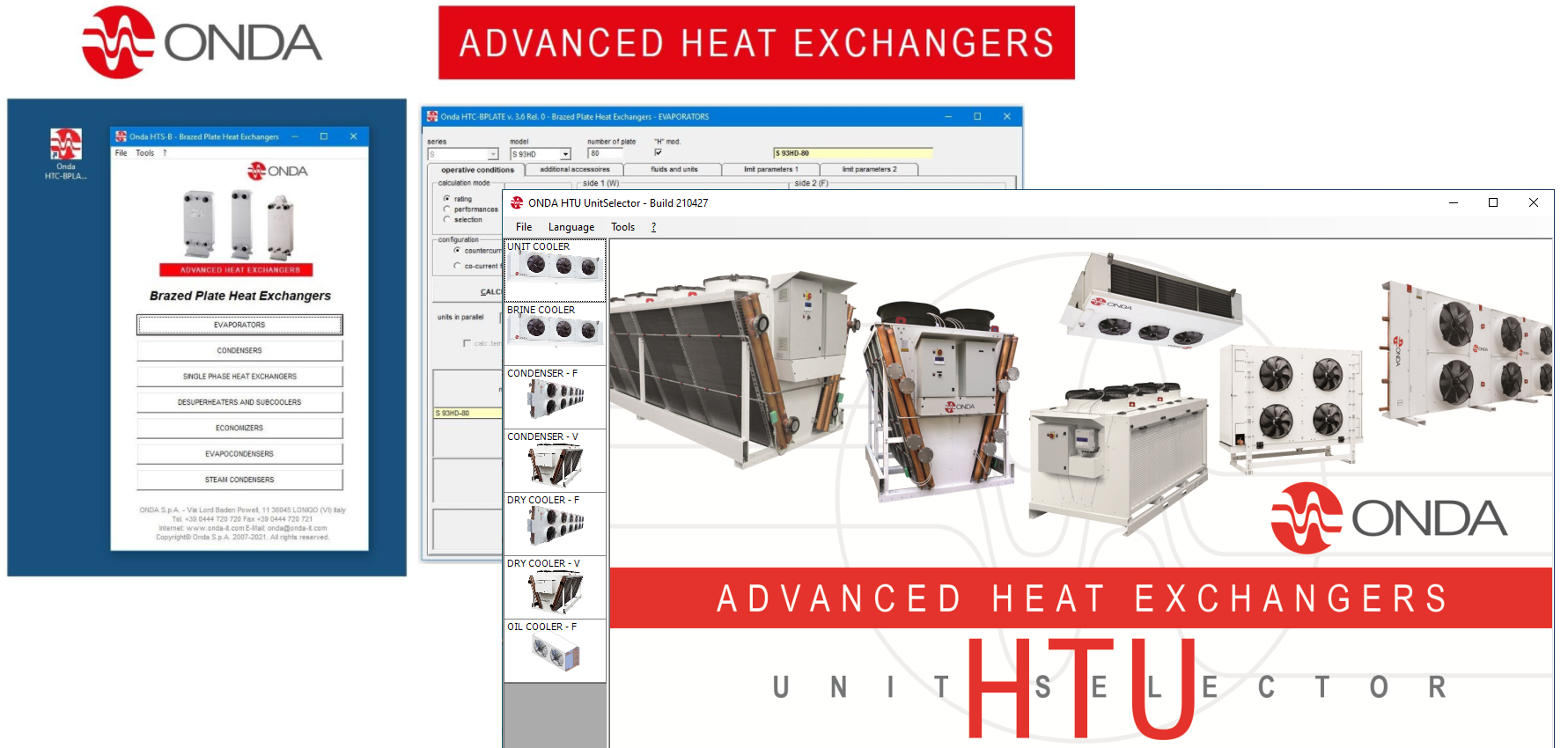

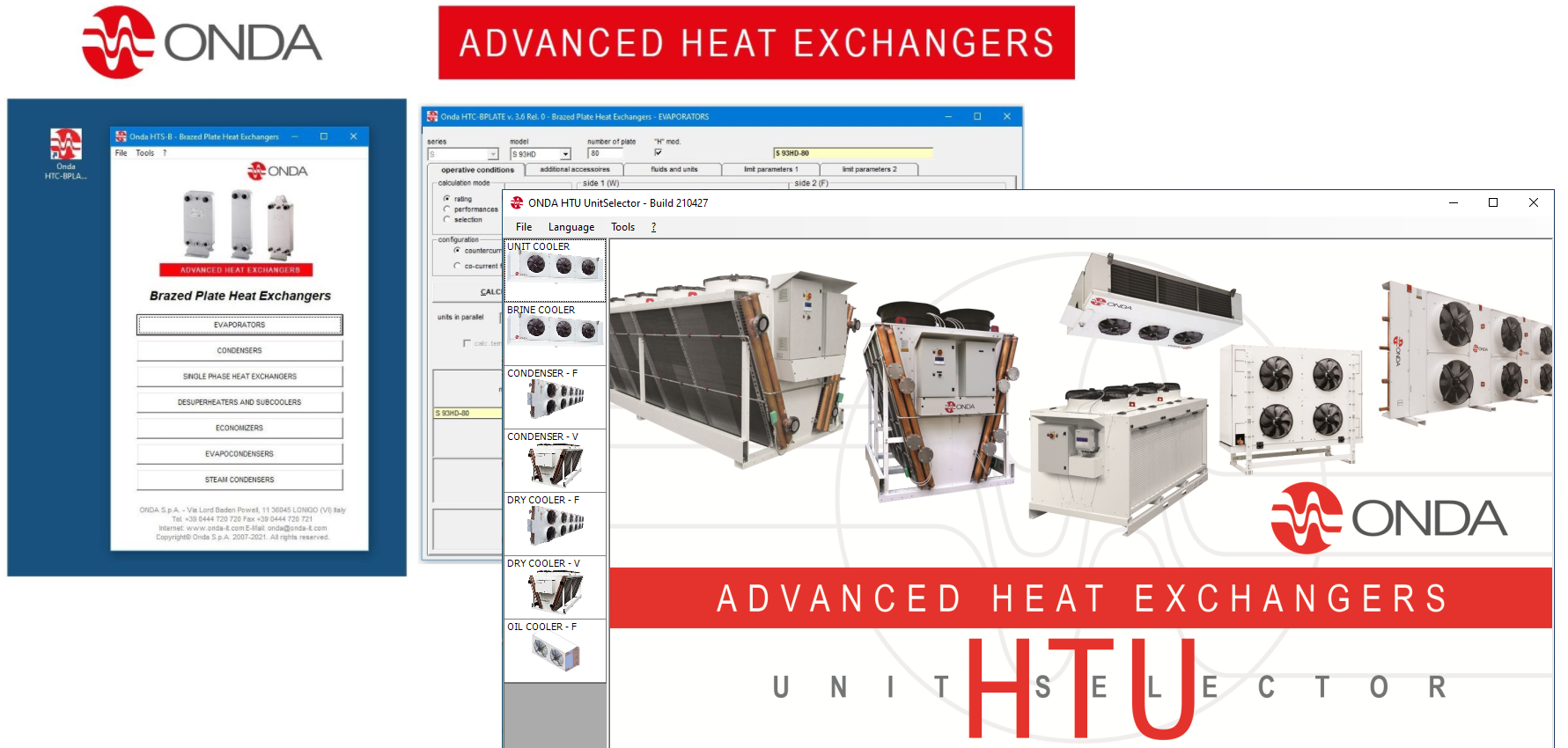

New Brazed and Air Software 2021

The new release of the selection software for the air products “UNIT SELECTOR HTU 211001” is now available on our website!

You will find the new V-shape range of dry coolers and condensers “FVD-CVD” and many other new features.

Download it now!

https://www.onda-it.com/eng/download/

New Air and Brazed software 2021

The new ONDA Brazed Plate Heat Exchanger HTC-BPLATE 3.6.0 and AIR UNIT SELECTOR 210427 software are available with new BPHE models and refrigerants !

Go to the download area to find it !

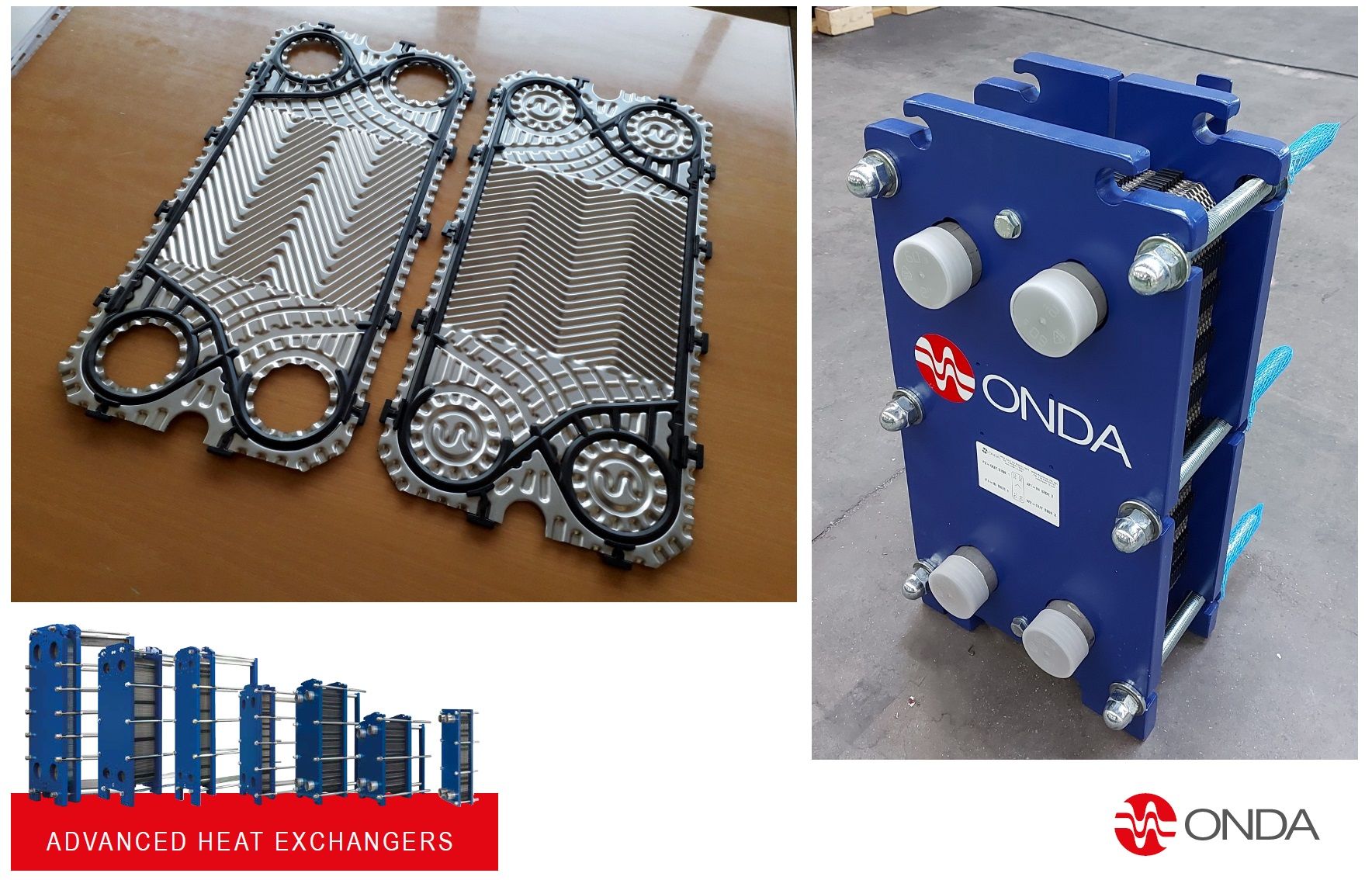

New Gasketed Plate Heat Exchangers GG004

Plate and Frame model GG004

Onda present the new model of gasketed plate heat exchanger, the GG004.

It have a DN50 - 2" AISI 316 connections and it can reach PN16 Bar.

The exchange plate are available in AISI316 - AISI304 - Titanium and the gasket in NBR - EPDM - VITON - HNBR.

New Brazed Plate Heat Exchangers S87 e S93

Onda is introducing the new BPHE models S87 and S93 for HVAC&R applications with boosting performance +30% vs current S82 in terms of kW/m2.

The design of the plate corrugations pattern has been optimized thanks to a CFD analysis supported by thermal laboratory test.

The new Wieland Onda brazed plates S93 and S87 have been developed to respond to high efficiency and low water pressure drop market demand using high pressure refrigerants as R454B, R32 and R410A

New patented distribution system which allows to achieve stable performance with large plate package.

BENEFITS VS S82

• Evaporator and condenser average performance: +30% kW/m2

• Lower DPwater -25% at same flow rate

• Stainless steel average weight saving : -20%

CONFIGURATION

• Capacity range 20 – 90 kW

• Two model range PS 30 barg, PS 49 barg